What is Hot extrusion,Advantages , Disadvantage and it's used of hot extrusion

Hot extrusion

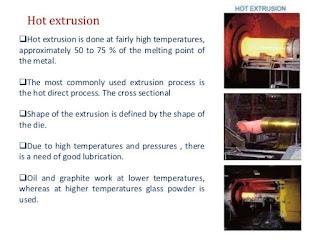

This is the process of closing a hot billet or metal snail in a closed cavity and then simply carrying it through a dye opening so that the metal will take the shape of an opening. Pressure is applied either hydraulically or mechanically.

The extrusion process is similar to squeezing toothpaste out of a toothpaste tube. The process of hot extrusion is used to number of Extrusion products liked tubes, rods, hoses, casing, brass cartridges, molding-trims, structural shapes, aircraft parts, gear profiles, cable sheathing, and more. Using the extrusion process, it is possible to create components, which have a continuous cross-section at any length through the rolling process.

The complexity in parts that can be obtained by extrusion is greater than rolling, as the dye is much simpler and easier to make. Also extraction is a single pass process unlike rolling. The rate of possible reduction in extrusion is large.

Normally brittle materials can also be easily removed. It is possible to create sharp corners and retract angles. It is also possible to get the shape with the internal cavity in the extrusion using spider dies, which is explained later.

The extrusion setup consists of a cylindrical container in which a hot billet or metal slug is loaded. At one end of the container, the die plate is fixed with the required opening. From the other end, the plunger or RAM compresses the metal billet against the walls of the container and the die plate, thus forcing it to flow through the die opening and acquire the shape of an opening. The extruded metal is then transported through a metal handling system as it exits the die.

The rate of extrusion is defined as the ratio of the extruded section of the cross-sectional area of the billet. Horizontal hydraulic presses with a capacity of 250 to 5500 tons are commonly used for conventional extrusion. The pressure requirement for extrusion varies from material to material. The extrusion pressure for a given material depends on the extrusion temperature, area reduction and extrusion velocity.

The extrusion setup consists of a cylindrical container in which a hot billet or metal slug is loaded. At one end of the container, the die plate is fixed with the required opening. From the other end, the plunger or RAM compresses the metal billet against the walls of the container and the die plate, thus forcing it to flow through the die opening and acquire the shape of an opening. The extruded metal is then transported through a metal handling system as it exits the die.

The rate of extrusion is defined as the ratio of the extruded section of the cross-sectional area of the billet. Horizontal hydraulic presses with a capacity of 250 to 5500 tons are commonly used for conventional extrusion. The pressure requirement for extrusion varies from material to material. The extrusion pressure for a given material depends on the extrusion temperature, area reduction and extrusion velocity.

Tags for hot extrusion process and application and advantages or disadvantage of hot extrusion

- hot extrusion

- hot extrusion process

- hot extrusion and cold extrusion forward hot extrusion

- major problem in hot extrusion

- hot extrusion and cold extrusion difference

- cold and hot extrusion

- hot extrusion of aluminium

- hot extrusion application

- hot extrusion ppt

- hot extrusion advantages and disadvantages

- hot extrusion diagram

- hot extrusion pdf

- the major problem in hot extrusion is

- hot extrusion of steel

- hot extrusion materials

- forward hot extrusion

- hot extrusion strain hardening

- does hot extrusion reduce the strength of the work material?

- indirect hot extrusion

- hot extrusion of tungsten carbide without

FAQ questions about hot extrusion process advantages benefits difference

What is hot extrusion and cold extrusion?

Ans.: Hot extrusion is a hot working process,it means it is done above the material's recrystallization temperature to keep the material from work hardening and to make it easier to push the material through the die.

Cold extrusion is done at room temperature or near room temperature

What is the process of cold extrusion?

Ans.:Cold extrusion can be defined as the process of shaping of a cold metal by striking a slug. This striking is done with a punch (in closed cavity), which forces the metal in upward direction around the punch. This process is also called Cold Forging, Cold Pressing, Extrusion Pressing, and Impact Extrusion

What is the meaning of extrusion?

Ans.:Extrusion is a process used to create objects of a fixed cross-sectional profile.

What advantage cold extrusion has over hot extrusion?

Ans.: Advantages cold extrusion over hot extrusion is below,

1.lack of oxidation

2.higher strength due to cold working

3.closer tolerances

4.good surface finish,

5.fast extrusion speeds .

What is hot extrusion used for?

Ans.The hot extrusion process is used to produce metal products of constant cross section, such as bars, solid and hollow sections, tubes, wires, and strips

What is another word for extrusion?

Ans. If you have any ask questions like above extrusion another word related like this are expulsion, extruder, intrusion, bulge, bump, hump, swelling

What are the advantages of hot extrusion over forging?

How extrusion dies are classified?

What are the disadvantages of extrusion?

What is extrusion and its types?

is cold forging stronger than hot forging?

Ans.:Cold forging improves the strength of the metal by hardening it at room temperature. Hot forging results in optimal yield strength, low hardness, and high ductility by hardening the metal at extremely high temperatures.

Post a Comment

0 Comments