Helical gears : Function, working, Application, Advantages with Material

Hello Readers, As you find article on How Helical gear works? Define Helical gears, And that's Advantage and disadvantage with their application.Also read Function of Helical gears.Types of Helical gears some few information like which material specific like to used Helical gears.also provide spur gear, herringbone Gear Definition .so enjoy reading.

|

| Helical gears : Function, working, Application, Advantages with Material |

Helical Gear types and their applications Aeronautics, mining, manufacturing chains in the automotive sector, pharmaceutical industry, textiles ... sectors and fields where you can find machines using different types of gears. In this article we are going to explain the most important methods of different types of gears.

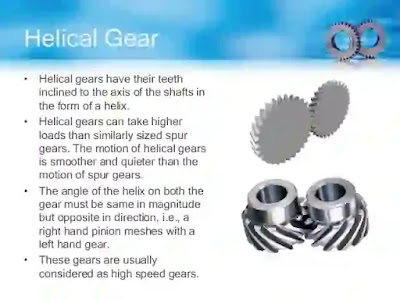

Helical gears Definition:

GEAR : Helical Gear is a rotating machine part having cut teeth which mesh with another toothed part to transmit torque. Geared devices can change the speed, torque, and direction of a power source.

Also read Material of Helical Gear,

The materials used in during manufacturing of helical gears are below:

various types of material like

steel,

aluminum,

bronze,

nylon etc.

industry, steel industry, textile industry, pump and pumping equipments, specialist machinery etc.

helical gears usually employ parallel axes configurations with mated gear pairs, but, if properly aligned, they can also be used to drive non-parallel, non-intersecting shafts. . However, unlike spur gears, these gears are constructed with teeth that turn at the gear face at an angle around the cylindrical gear body. Helical gears are generated with right-hand and left-hand teeth, with each gear pair having right-hand and left-hand gears of the same helix angle.

The angled design of the helical teeth allows them to engage with other gears, which are different from the straight teeth of spur gears. As properly matched helical gears come into contact with each other, instead of engaging the entire tooth at once, the level of contact between similar teeth increases gradually. This gradual engagement allows low impact loading on the teeth of the gear and smooth, quiet operation. Helical gears are also capable of greater load capacities but operate with lower efficiency than spur gears. Further disadvantages include the complexity of the helical tooth design, which increases the degree of difficulty in its construction (and, as a result, the cost) and the fact that the single helical gear tooth design produces axial thrust, including thrust bearings. Employment requires any application which uses single helical gear. This latter requirement further increases the total cost of using helical gear.

Since helical gears are also capable of handling high speeds and high loads, they are suitable for the same types of applications as spur gears, such as pumps and generators. Their smooth, quiet operation also suits them for automobile transmissions where spur gears are not commonly used.

Single or double helical gear design

Helical gears are available in single helical and double helical designs. Single helical gears have the same line of angled tooth cut or inserted around the circumference of the gear body, while double helical gears have two mirror roars of angled tooth. The advantage of the latter design is its greater strength and durability (compared to the single helical design), and the elimination of axial load generation.

Gears and their teeth SO gears are classified:

parallel axis and perpendicular axis

According to the position and size of their teeth. In this sense, they are classified into parallel axis and non-parallel axis gears.

Parallel axis gears:

The parallel axis gears include spur, helical and double helical cylindrical gears.

Double helical gear

spur gears.

Helical gears.

Non-parallel axis gear:

Screw gears

Spur or straight bevel gears

Spiral bevel gears

Hypoid gears

Worm wheels and worm screws

Benefits of auxiliary gear:

Advantages of Helical gears

- The angled teeth join more slowly, causing the spur gear teeth to escape, allowing them to run more easily and quietly.

- Helical gears are highly durable and ideal for high load applications.

- Helical gears can be used on non-parallel and even vertical shafts, and can carry more load than loading gears.

- At any given time their load is distributed over many teeth, resulting in less wear.

- Can transmit speed and power between parallel or right-angled shafts.

Additional helical gear design

Other types of helical gears include herringbone gears and screw gears.

Herringbone Gear Definition:

Herringbone: Herringbone gear is a type of double helical tooth in which the two rails of the tooth touch rather than separate from a groove, forming a "V" shape similar to the herringbone pattern.

Screw Gears Definition:

Screw: Screw gears, also known as overhead gear, are helical gears used for non-parallel, non-intersection configurations. Unlike helical gears used for parallel configurations, screw gears employ the same hand pairs instead of right hand and left hand gears per pair. These gears have relatively low load capacity and efficiency rates and are not suitable for high power transmission applications.

Application of Helical gears:

- Helical gears Helical gears are generally preferred to work under heavy loads.

- Helical gear is used in fertilizer industries, printing industries and earth moving industries.

- Helical gears are also used in steel, rolling mill, section rolling mill, power and port industries.

- Helical gears are also used in textile industry, plastics industry, food industry, conveyors, elevators, blowers, compressors, oil industries and cutters.

- power industries, steel and rolling mills

Textile industry, food industry, plastics industry, elevators, conveyors, compressors, blowers, cutters and oil industries .

Post a Comment

0 Comments